News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

How to choose metal corrosion protection?

- Author:Libo

- Source:wm.gofitnessfreak.com

- Date:2021-10-22

- Click:0

With the exception of a few precious metals such as gold and platinum, most metals are corroded in air and water. A simple principle for preventing metal corrosion is to isolate the metal from the corrosive environment. Anticorrosion methods are summarized as follows:

(1) Non-metallic protective layer. Apply corrosion-resistant non-metallic materials, such as paint, spray paint, enamel, ceramics, glass, asphalt, and polymer materials (such as plastic, rubber, and polyester) on the metal surface to isolate the metal from the corrosive medium.

(2) Metal protective layer. Use metal or alloy with strong corrosion resistance to cover the protected metal surface, covering methods include electroplating, thermal spraying, vacuum plating and so on. According to the electrochemical properties of corrosion prevention, the protective layer can be divided into anode protective layer and cathode protective layer. The standard electrode potential of the anode protective metal is lower than that of the base metal, such as galvanized iron plate, where zinc is the anode and iron is the cathode. The standard electrode potential of the cathodic protection metal is higher than that of the base metal, for example, tin plate, tin for the cathode, iron for the anode. There is no principle difference between the two coatings in their ability to separate metal from the environment. But when the protective layer is damaged and becomes incomplete, the situation is different. As mentioned earlier, the cathodic protection will anodize the base metal, causing pitting. Anode protective layer, such as galvanized iron plate, zinc is the anode, the base metal iron is the cathode, corrosion is zinc coating, rather than iron. The base metal does not begin to corrode until the coating is too damaged to protect the base metal.

(3) Electrochemical protection.

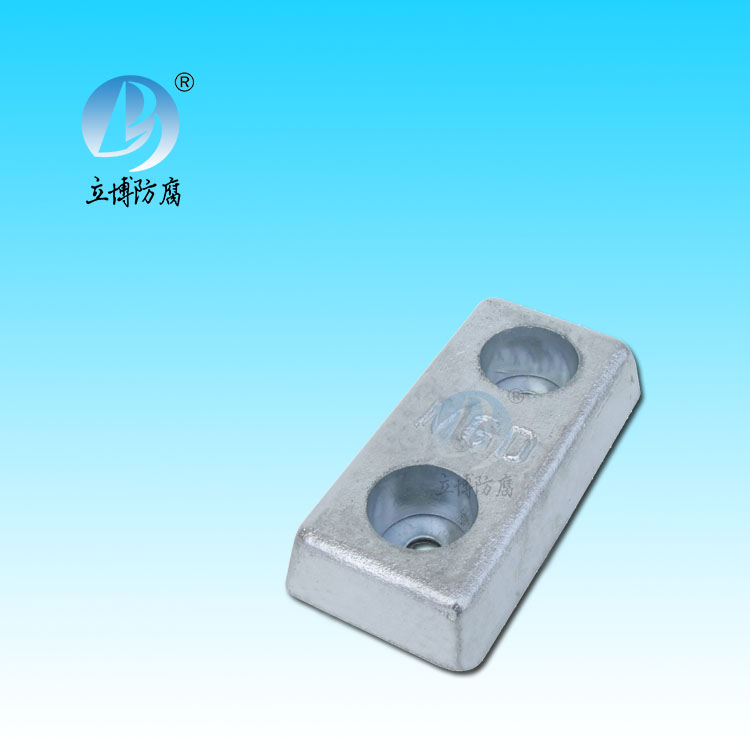

(1) Sacrificial anode protection: connect the metal with low potential of the standard electrode and the metal that needs to be protected to form the battery. At this time, the metal that needs to be protected becomes the cathode due to high electrode potential, which is protected from corrosion. Another metal with a low electrode potential, the anode, corrodes. For example, ships sailing at sea are inlaid with zinc blocks around the bottom. In this case, the hull is the cathode, protected, and the zinc block is the anode, instead of the hull being corroded. This protection law protects the cathode and sacrifices the anode, so it is called sacrificial anode protection law.

Cathodic protection: this is the use of external power to protect the metal. The metal to be protected is connected to the negative electrode as a cathode to prevent corrosion. Take some iron and attach it to the positive electrode, make it an anode, let it corrode, and actually sacrifice the anode. Unlike the above method, the current is provided by an external source, rather than by the battery itself. Some acidic solution storage tanks or pipelines of chemical plants, as well as underground water pipes, pipelines, and so on, commonly used this method anticorrosion.

客服QQ

客服QQ